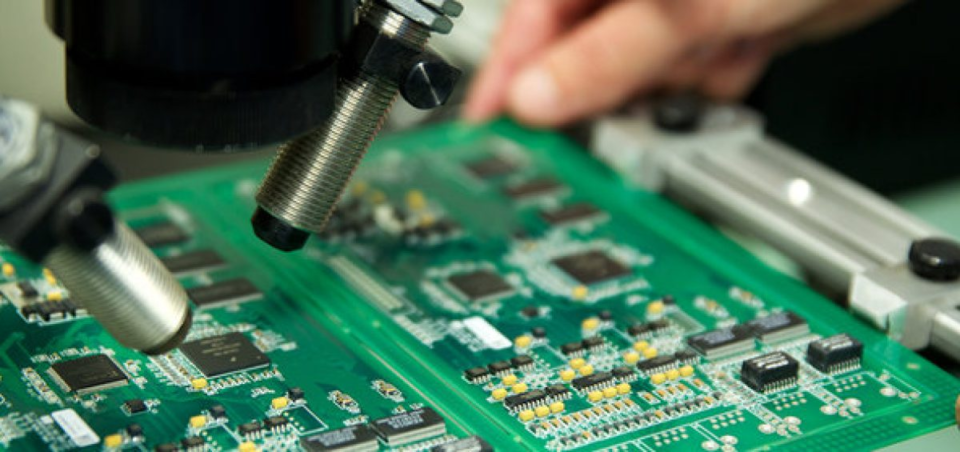

If you’ve ever wondered what goes into PCB manufacturing, read on for an explanation of the process. This article will walk you through the process’ Design Principles, the Processes used to produce a PCB, and the Cost associated with PCB production. If you’re wondering what goes into PCB production, read on! We’ll cover everything from the cost of PCBs to potential problems that can arise during the process.

Design principles that affect PCB manufacturing

There are several design principles that affect the manufacturing process of PCBs. The basic principles are layout, component placement, and sizing. The layout of components determines how neat the board will be, as well as the length of the printed wires. These principles also impact the reliability of the entire machine. When creating a design for a PCB, it is crucial to understand the limitations and benefits of each. The following is a list of design principles to consider before drafting your PCB layout.

First, PCBs should be designed with the least amount of changes. The PCB materials chosen should be such that they are robust and will not suffer any degradation even under the harshest conditions. The circuit schematic shows how the PCB will implement each function electrically. Circuit schematics should include the areas where circuit schematic blocks should be placed. These are groupings of components that are closely connected for electrical reasons. The PCB should be designed so that all components are close to each other.

Processes used to manufacture a PCB

PCB manufacturing begins with a process called photo-transfer printing, which involves attaching a dry photosensitive film to a copper substrate. Under UV light, the dry film polymerizes, transferring a pattern to the copper surface. The unpolymerized film is then dissolved in a sodium carbonate solution, leaving the exposed copper exposed. The polymerized dry film is then removed with a film remover and the copper is then etched to produce the circuit traces.

After the engineering process is completed, the PCB must be assembled and soldered. In addition to the soldering, the PCB requires a surface finish. A surface finish prevents copper from oxidizing, which makes it impossible to solder it. Hot air solder level is the most common surface finish and is offered in both lead-free and leaded versions. Other finishes may be needed depending on the PCB’s specifications, application, or assembly process.

Problems that can occur during PCB manufacturing

During PCB manufacturing, mistakes can cause PCBs to fail. PCB failures can be caused by design oversights, manufacturing processes, or a combination of these issues. While some of these problems are beyond the designer’s control, paying attention to these details will help to avoid these issues. These mistakes can result in a lower-quality finished product. To avoid these issues, follow these PCB manufacturing tips.

High temperatures can cause PCB components to burn out. If soldering is not done properly, components may be too close together. The heat generated from soldering can cause components to burn out. Therefore, PCB manufacturers should keep an appropriate space around all components to prevent this from happening. Besides the PCBs themselves, bad solder and loose components can cause the same problems. Ultimately, these defects can lead to expensive repairs.

Cost of PCB manufacturing

A major part of the cost of PCB manufacturing comes from the raw materials used for production. These materials include copper foil, balls, substrates, prepregs, inks, dry films, and gold salts. Copper foil and balls account for more than half of the material cost. Copper-clad laminates, used in the construction of printed circuit boards, account for about 37% of the cost. The costs of these materials are spread out across a variety of application areas.

The quantity of PCBs needed can drastically affect the cost of PCB manufacturing. The higher the quantity, the lower the unit price of PCBs produced. The cost of PCB assembly decreases as the quantity increases. Higher-volume PCB manufacturing also helps to prevent one-time costs, as the factors that increase the cost of the initial unit don’t affect subsequent units. Therefore, companies should try to order their PCBs in bulk to avoid paying for one-time costs.

Ready to get started on your project? Contact this PCB manufacturing AZ company today.